Back to the roots, shaping the future – At a glance

Made in Germany

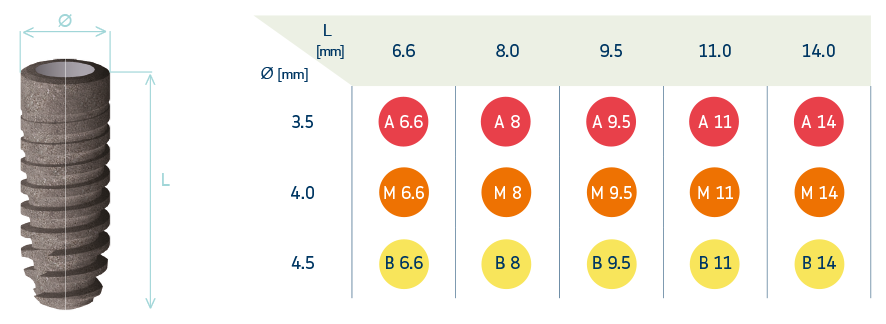

The myplant two system

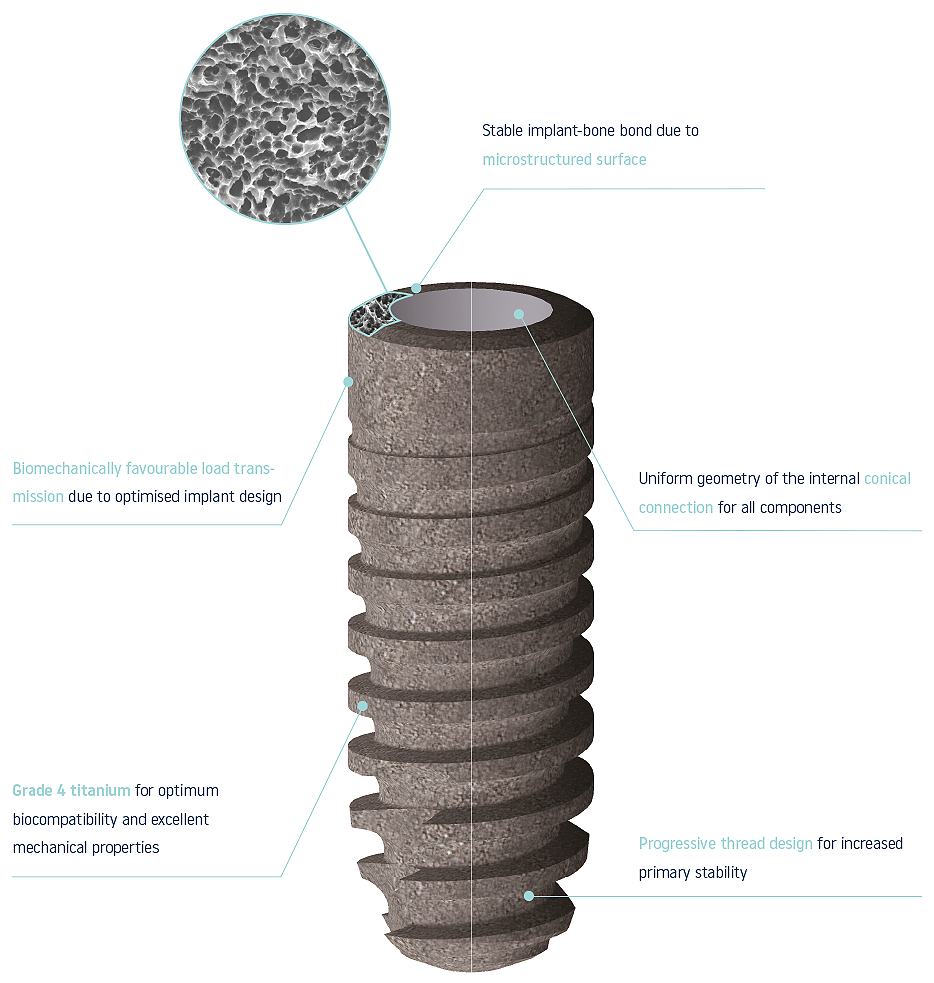

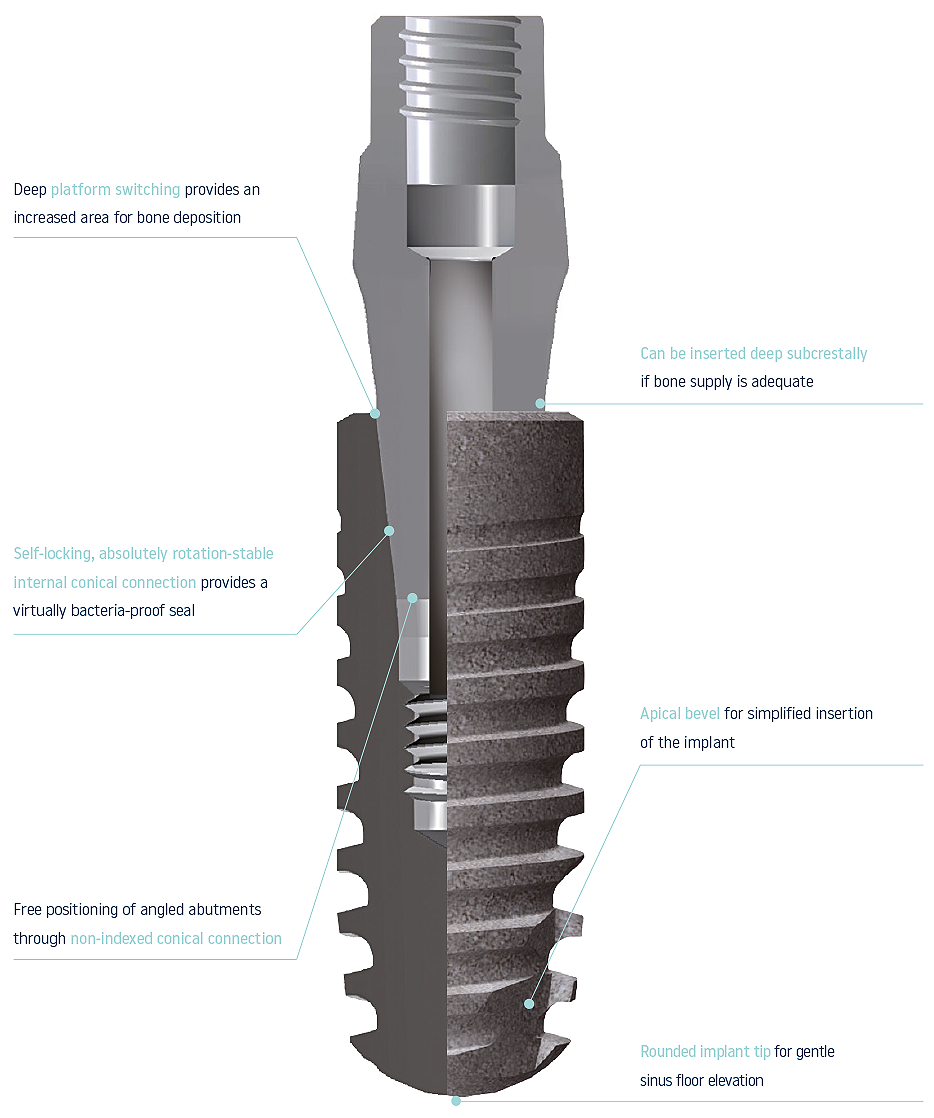

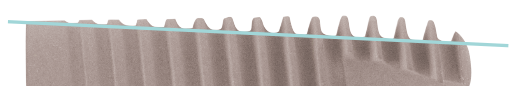

The concept of a two-phase titanium implant with special expansion thread and self-locking cone as abutment connection was developed by Prof. Dr. med. dent. Nentwig and Dr. Ing. Moser 30 years ago and brought to clinical maturity. High primary stability, minimum construction height, a micro-movement-free and bacteria-proof implant-abutment connection as well as a deep platform switching soon proved to be a superior combination in terms of achievable bone and soft-tissue stability, thereby ensuring exceptional long-term success.

With the myplant two implant system, Prof. Nentwig and Dr. Moser have further advanced and optimised this concept, which has been documented over decades, and adapted it to the criteria of modern, future-oriented implant therapy.

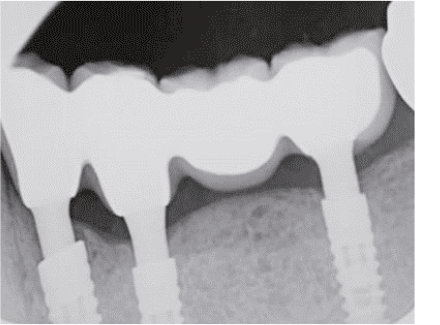

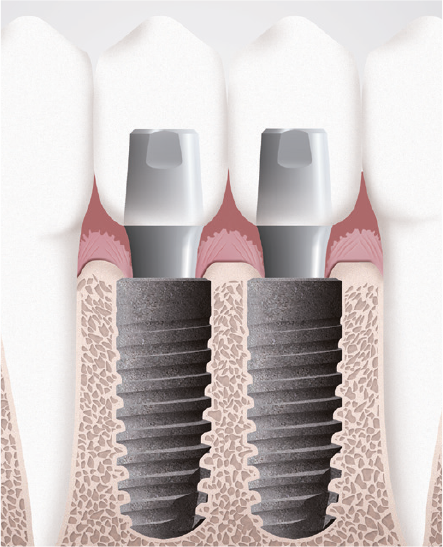

The deep platform switching and resulting broad implant shoulder allow for more approximal space at abutment level than non-conical connections. Together with the bony deposition on the implant shoulder, this is critical for establishing a stable and healthy soft-tissue cuff and consequently for aesthetics. This achievable even with tightly placed implants thanks to the enlarged approximal space.

The deep platform switching and resulting broad implant shoulder allow for more approximal space at abutment level than non-conical connections. Together with the bony deposition on the implant shoulder, this is critical for establishing a stable and healthy soft-tissue cuff and consequently for aesthetics. This achievable even with tightly placed implants thanks to the enlarged approximal space.

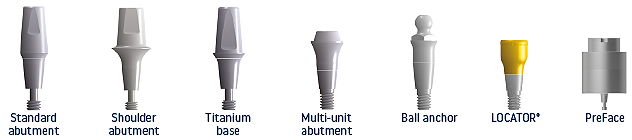

The various abutment series allow for friction-based, screwed-in, glued or cemented attachment of the prosthetics.

The various abutment series allow for friction-based, screwed-in, glued or cemented attachment of the prosthetics.

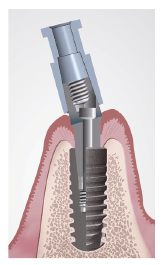

The screwdriver (ZSD0L) is inserted in the lateral screw channel and the screw is com-pletely loosened. The revision sleeve (ZRH01) is applied over the abutment. The revision instrument is inserted turning clockwise into the drill-hole of the revision sleeve until the abutment detaches from the implant cone.

The screwdriver (ZSD0L) is inserted in the lateral screw channel and the screw is com-pletely loosened. The revision sleeve (ZRH01) is applied over the abutment. The revision instrument is inserted turning clockwise into the drill-hole of the revision sleeve until the abutment detaches from the implant cone.